Authored by attending Ecosystm analysts, Ullrich Loeffler (Chief Operating Officer), Kaushik Ghatak (Principal Advisor, Digital Transformation and Supply Chain) and Liam Gunson (Director, Product and Solutions)

Bosch Software Innovation (Bosch SI) hosted its annual analyst briefing in Singapore on 6th December 2019 to provide an update on its business, strategy and solution portfolio in the APAC region.

Bosch has expanded its capability and reshaped its go-to-market approach in a bid to not only position itself as a world leading IoT company, but also help move the IoT market forward.

A number of new solutions were demonstrated through the day. From tenants asking their building management if the gym was busy, to smartphones detecting a manufacturing fingerprint so you could avoid buying a counterfeit.

At the heart of the business updates though was a new organisational approach to prove markets and integrate user perspectives into solution development. Bosch is looking to achieve this by setting up dedicated, cross-divisional entities which can focus on user needs to drive growth while collating requirements for the Bosch SI centres.

Bosch SI essentially will perform a role of an IoT business incubator within Bosch Group, and once a vertical within Bosch SI has reached a certain level of business, it is spun off into a separate company focusing on that area. There are three business units that have met the threshold and have spun off so far.

Broader challenges still remain for IoT adoption. Patchy connectivity, varied regulation, and a lack of standardisation will continue to hamper the IoT market. However, from a user perspective the timing is right. Ecosystm research shows that while IoT uptake is limited, intention is strong. Enterprises will be looking for partners with a willingness to understand their needs and design around them, in order to help get initial projects off the ground.

Bosch Business Update – From Innovation to Commercialisation

Bosch SI was created to build Internet of Things (IoT) solutions, leveraging Bosch’s 133-year experience in developing and manufacturing products for the automotive, industrial and consumer segments. Founded in 2008, by 2019 Bosch SI has established 10 global offices, of which some have solution development capabilities, employing over 700 IoT experts. Four of the Bosch SI offices are located in Asia Pacific – Singapore, Nanjing, Shanghai and Tokyo.

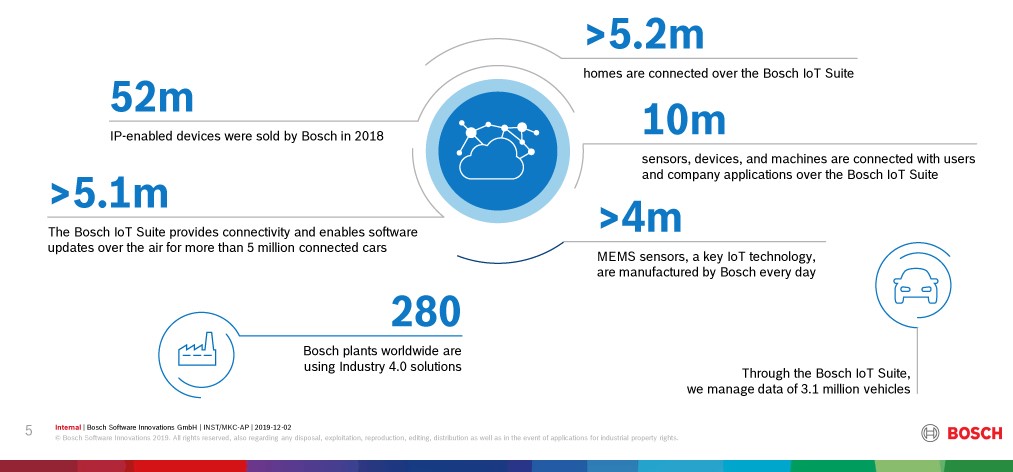

Figure 1: Bosch Software Innovations in Numbers

The Bosch IoT Vision and Strategy is not limited to Bosch SI’s but spans across the full Bosch Group. An indication of the dedication to the IoT story is that Bosch is committed to enabling connectivity for all existing product portfolios ranging across its industrial, automotive, manufacturing and consumer product lines by 2021.

Another indication of Bosch’s IoT business maturing is that in 2018 Bosch it formed 3 new subsidiaries, each being a dedicated entity to take targeted IoT Industry solutions to market. The new business entities focus on

- Connected Industry

- Connected Mobility

- Residential IoT

with other areas such as Agriculture, Retail, Energy, Mobility, Manufacturing and Home & Building as potential future spin-offs. The announcement is significant as it separates the innovation and commercialisation functions. Bosch SI becomes the dedicated R&D and incubation engine to take new industry solutions to a defined threshold before a dedicated entity is formed to achieve commercial scale.

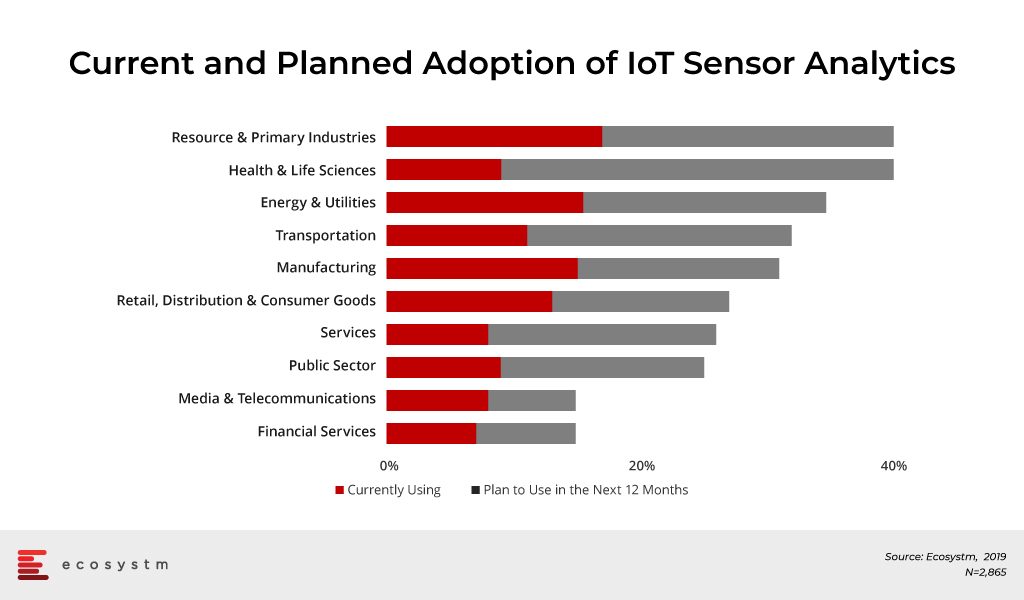

Despite the fact that IoT has been greatly overhyped since the term was coined by Kevin Ashton in 1999, Ecosystm research shows evidence that adoption is accelerating across the region. Figure 2 outlines the current and planned adoption of ‘sensor-based analytics’ within organisations. The research strongly supports Bosch’s timing for investments in scaling the commercialisation of its solutions.

Figure 2: Industry Adoption of Sensor-Based Analytics

Market Pull over Technology Push is creating proven Industry Use Cases

The locations and specialisations of Bosch’s Innovation Centres across Asia are no accident and result directly from engagements with local clients. Each innovation centre specialises in certain solutions that have arisen from the productisation of solutions developed for customers. This ‘market pull’ strategy is a clear differentiation to the commonly practiced ‘technology push’ approach which has seen many vendors struggle to gain traction for their IoT solutions. Key industry solutions developed by Bosch SI are:

- Agriculture – Bosch Plantect: (Japan). Plantect is a sensor-based monitoring system for early detection and prevention of plant diseases in greenhouses. The current solution targets greenhouse farmers for tomatoes, cucumber and strawberries.

- Smart Building – Bosch Lift Manager (Singapore). Lift Manager is an AI-supported solution that can be retrofitted in existing lifts with set algorithms to monitor and predict lift malfunctions and enable predictive maintenance.

- Smart Building – Connected Buildings (Singapore). Bosch Connected Building leverages cameras and sensors to optimise business operations such as Air Quality, Light Monitoring & Control, Lift Monitoring, Occupancy Tracking, Asset Tracking, Carpark Monitoring, and Object Tracking.

- Manufacturing – Secure Product Fingerprint Solutions (China). Secure Product Fingerprint captures a unique fingerprint for products to combat counterfeits and connect manufacturers with their users.

The Bosch IoT Ecosystem – Open Source and API enabled Platform

Bosch has realised that IoT is a concept that cannot be owned and delivered by a single entity. As such Bosch aims to establish its Bosch IoT Suite as the platform to connect any Bosch or third party “things” to deliver targeted industry services and solutions.

Bosch IoT Suite can be deployed on Bosch’s own IoT Cloud or through Cloud partners such as AWS, Microsoft or Huawei (for China only). It is a PaaS offering that packages unified device APIs to connect things with device management, software updates over the air, data management and security capabilities. An inbuilt analytics engine assists with business logic tools to drive business value out of the data collected. The open source and open standards architecture promote the development of in-house or third-party industry applications as platform add-ons and use cases.

Bosch and Market Outlook

IoT has been one of the most hyped ‘buzz words’ for the last few years but true market adoption is yet to follow suit. Ecosystm research shows that market intention is positive with more industry-focused uses cases and simpler ‘plug and play’ style solutions available that require less CapEx and shorter time to value.

Bosch is well positioned to capitalise on this trend. Its focus on developing proven use cases for targeted industry sectors and then working with anchor customers and testing the solutions internally within Bosch, is a clear differentiator in the market. Commercially scaling these solutions will remain the key challenge as decision stakeholders may not be the key beneficiary of the solution. In the connected building example, tenants will be the key beneficiary of finding quiet gym slots or having better air quality but it remains questionable whether this will convince the building owner or operator to put pen to paper and sign-off on relevant IoT investments. An area that Bosch needs to focus on, is the articulation of its business proposition and more importantly connect this to the business value to prospects and customers. As solutions scale in the market, broader sales and partner teams will need to be enabled to bring this message to the relevant stakeholders. The fact that these stakeholders may sit outside Bosch’s traditional comfort zone will not make this endeavor easier.

Bosch will also face varying market regulations that could create road bumps in scaling its solutions. The Bosch Lift Manager solution as an example provides sensor diagnostics for predictive maintenance scheduling. Many existing lift maintenance contracts however follow local regulations that require ongoing scheduled servicing of elevators which reduces the cost savings potential.

The decision to establish standalone IoT entities is seen as a strong commitment and the right move to take advantage of the presented IoT opportunity. The high degree of customer advocacy and industry experience further makes Bosch a strong contender of the Industry 4.0 revolution.

I had the pleasure of attending the Industry of Things World 2019 in Berlin. Berlin has always fascinated me by its contradictory image – of modernity and traditionality. Their admired industrial companies can be conservative in terms of innovation and move slowly when adopting new technologies. However, once they decide to move, they move all at once and cause a significant change in the industry. And that is what I perceived at the event.

In Berlin, companies know what Industrial IoT (IIoT) is and IIoT solution providers’ efforts focus on how to implement IIoT. The level of adoption in the DACH and Nordic regions is higher than in other European regions but still remains low, especially in small and medium enterprises (SMEs).

The first thing that was highlighted at the event is that AI has not devoured IoT. Organisers do not try to fill auditoriums and beat attendee figure records with other parallel events of AI, Blockchain, AR/VR, 5G, DevOps and so on.

It was interesting to listen to both tech buyers and vendors sharing their news and vision – clients such as Rolls Royce and thyssenkrupp sharing their implementation experiences and giving recommendations on how to succeed in IIoT projects and; IIoT vendors such as Cumulocity IoT, HPE, AWS, Siemens or Huawei presenting their capabilities. All of them are clear that IIoT must be part of a new paradigm of business systems integration.

Key Takeaways:

- In the several round tables that I attended, the ideas and conclusions presented were very educative. It was good to listen to the main actors (the actual companies implementing IIoT) talking about their challenges, requirements, solutions and desires. Most of the CEOs are in consensus on their priorities in IIoT investments: ROI, Performance and Quality.

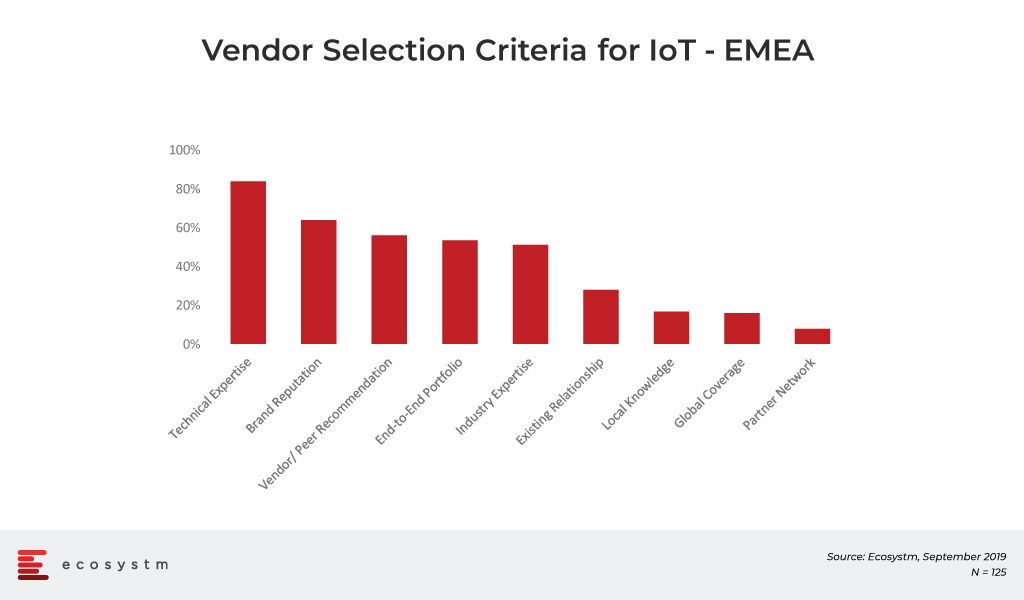

- I validated with organisations the results of the Ecosystm IoT study regarding their vendor selection criteria for IoT projects. This ties back to their IIoT investment priorities. They are likelier to choose vendors that can deliver on all 3 of their priorities.

- The most realistic statement about IIoT came from the HPE speaker, “Don’t look for disruptive companies like Uber in the Industrial Internet of Things market.” Here the new business models will take time to emerge. Other exhibitors and visitors, that I had conversations with, agreed with this idea.

- Fortunately for the IIoT market in Germany and Europe at large, China continues to adopt these technologies at a similarly slow pace. Although China may be more advanced in digitalisation (in ePayments for example), when it comes to IIoT, they are as conservative as Europe. This gives us a window of opportunity to continue to evolve our offerings, in the region.

- Another recurrent theme through the event was the inability and hesitance of the CEOs/ CFOs/ Boards to understand the potential of data-based collaboration between companies and industries and how they continue to kill any data sharing/open data initiatives. Walled gardens should not be a medium-term objective.

- The presence of start-ups and enthusiastic entrepreneurs was very heartening – and while I could not speak with all of them, CloudRail, Juconn, TechMass , Ekkono and WolkAbout stood out in my opinion. And of course there were some IIoT Platform vendors such as AWS, Cumulocity IoT, Device Insight, Relayr and Waylay. As I have said many times it is not necessary to analyse 400 platforms – for each local, regional or global enterprise there is a maximum 3-4 platform superheroes vendors to select.

- I had some conversation on IoT connectivity with LumenRadio, SigFox and Multefire However the session discussing the impact and need for 5G in IoT was shallow because the speakers only covered high level use cases and benefits of 5G and how the German government is working on security requirements for end-to-end 5G services.

- Finally, it was great to hear people talking about IoT lifecycle management. It has become clear that IoT is real and is here to stay. Some companies have already passed the Proof of Concept stage. This reassures us that IoT is not just ideas, development and pilots. IoT projects are going beyond and thinking about operations and maintenance.

Congratulations to all nominees in the first Industry of Things World Award ceremony. The winners were Fette Compacting in the category, Best Implementation of IIoT Technology on the shop floor and BAM GmbH up2parts in the category, Best IIoT Product or Service.

One final observation on the event is the disparity in the number of men and women attending. I got the impression that not many women are involved in IIoT or at least they do not attend events such as this. I hope that skills training and the market potential will attract more women to this industry in the future.

So dear friends, contacts, followers and readers: in short, the event was a positive experience and I hope to see some medium-term outcomes in

For years, I have been writing about the promise and perils of the Internet of Things (IoT). In many of my articles, I described how the IoT could help transform society and kickstart the next industrial revolution. However, still many people and enterprises are not deploying IoT. We still cannot define in a unique and clear way what IoT is, much less explain how it will change our lives, without using the example of the smart refrigerator!

Why are we still at a loss with IoT? Let´s explore.

Lost in IoT Connectivity

With so many IoT connectivity options in the market, choosing the right one for your project can be complicated. It is a scary thought that billions of devices could be connected in a few years to decentralised IoT networks, with no interconnectivity between them, unless we use millions of edge nodes that transfer messages between devices connected in multiple networks. If it is already difficult to justify the ROI of a use case using a single type of connectivity – it is almost impossible to justify that these devices will need to communicate with other devices on different IoT subnets.

It seems that it is easy to get lost in so much connectivity technology. Isn’t that true?

Lost among hundreds of IoT Platforms

At least we can already intuit some of the platforms that will survive among the 700+ that some analysts have identified. I have only been able to analyse about 100 of them in some depth. Surely my methodology of Superheroes and Supervillains will advance the end of most of them.

It is no longer just one IoT Platform. Although they want to make it easy for us, companies like AWS, Microsoft or Google add concepts such as Serverless, Data Lakes, AI, Edge Computing, DLT and all the artillery of Cloud services to the core features of the IoT platform. It is easy to get lost in the architecture.

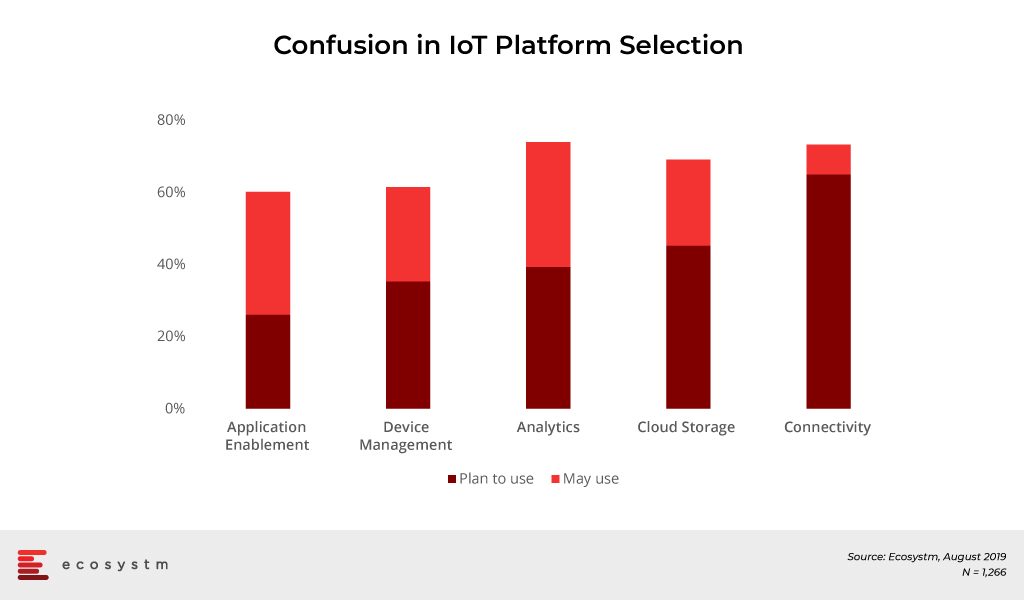

Data from the global Ecosystm IoT Study shows this confusion in selecting the right platform for future adopters of IoT. Same organisations indicate that they will use or at least evaluate several platforms.

Initiatives such as Verizon’s focus on connectivity and systems integrators abandoning their in-house developments to embrace leading vendors’ offerings, will reduce some of the confusion around IoT platforms.

Lost between the Edge and the Cloud

In “Do not let the fog hide the clouds in the Internet of Things”, I had warned about the degree of complexity that Fog /Edge Computing will add to the already complex IoT solutions. Now nothing seems to be of great value unless Edge Computing is included.

The Babel tower of alliance and consortia is consolidating, but people still get lost in the acronyms. News such as the merging of the Industrial Internet Consortium (IIC) and the OpenFog Consortium (OpenFog) to combine the two largest and most influential international consortia in Industrial IoT, fog and edge computing, has been hailed by many. The Open Group Open Process Automation Forum (OPAF) is defining the next generation edge computing standards for industrial operators.

And again, the question arises, do all organisations need Edge to start an Industrial IoT project?

Lost in Proofs of Concept

Businesses are estimated to be spending USD 426 Billion worldwide on IoT hardware and software in 2019 alone. Yet, three out of every four IoT implementations are reported to be failing.

Microsoft launched a new research report – IoT Signals – intended to quantify enterprise IoT adoption around the world. The survey of over 3,000 IT team leaders and executives provides a detailed look at the burgeoning multi-billion-dollar segment’s greatest challenges and benefits, as well as related trends. Perhaps it is not surprising that 30% of respondents say their IoT projects failed in the proof-of-concept (PoC) stage, often because the implementation became too expensive or the bottom-line benefits were unclear.

There are technical reasons – for example the use of Rasberry Pi or Arduino boards in the PoC and then later realising that more expensive hardware is needed for the actual project. There are economic reasons when organisations try to escalate their PoC to real implementations and then the ROI does not look as good as in the pilot.

There are organisational reasons when leaders are failing to go all in. If you cannot get the CEO on board, then the probability that your IoT project will end at the PoC stage is almost 100%.

If you are lost in the PoC, these tips can help you implementing IIOT.

- Solve a problem worth solving

- Keep it quick and simple

- Manage the human factor

Lost in selecting the right IoT Ecosystem

Today no significant ecosystem or network of collaborators has emerged in the IoT arena in spite of early and very interesting efforts being made by several players. Since I wrote “The value of partnership in Industrial Internet of Things”, I have heard, read and repeated hundreds of times how important it is to belong to an IoT ecosystem and how difficult it is to choose the one that suits you best.

Those who have read my articles know that there is no company in the world, no matter how great it is, that can do everything in IoT. Creating an IoT ecosystem either horizontal (technology) or vertical (industry) requires a lot of talent managers able to maintain win-win transactions over time. And according to the results, it appears to me that it is becoming very complicated.

Remember, you are not the only at a loss with IoT

When it comes to achieving an ROI from IoT, businesses really need to rethink how they are deploying it and ensure that they can manage their sensors remotely, secure their assets, use the sensors and devices data to make better real-time decisions and monetise it. However, for that to happen and to prevent the IoT projects from failing, businesses need independent and expert advice at several levels to find the right people to lead the project and the right technology and partners to make implementations successful.

IoT, Industry 4.0, Industrial IoT (IIoT), odds are that you have heard these terms used around you recently. IoT in the consumer space is a pretty straightforward concept to understand. IoT is an interconnected world of computing, mechanical and digital devices such as in a smart home consisting of thermostats, webcams, smoke detectors, smart doorbells who can talk to each other and managed from the internet or a smartphone.

On the other hand, when we look at things at a larger scale or we can say, an “industrial scale” then it is a whole new IoT world. Industrial internet of things (IIoT) is an extension of IoT and is the use of IoT largely in manufacturing applications, and supply chain management. IIoT is driving the next wave of the industrial revolution or we can say it’s opening a gateway to ‘Industry 4.0’. The key idea driving Industry 4.0 is a connected world comprising humans, machines, sensors and data working together in real-time to transform business and manufacturing processes.

A traditional manufacturing environment application works by connecting machines to a centralised data centre. The pain points here are there isn’t any interconnection between machines, the latency rate is high and processes are manual and thus prone to errors. Contrary to this, IIoT puts a modern approach and makes processes decentralised. IIoT makes machine interconnection possible converting them into automated and smart processing units. With IIoT machines have the ability to talk to each other in their own Machine to Machine(M2M) language.

The basic components that drive an IIoT system are:

- Secure intelligent assets such as sensors and smart controllers – that can sense, communicate, store and transmit information

- Communication and data storage infrastructure – often cloud-enabled

- Data analytics and smart business apps that generate information from the data

- Skilled workforce

How IIoT Can Revolutionise an Industry

IIoT is transforming the manufacturing industry and other supply chain intensive industries by maximising efficiency, reducing downtime and increasing the overall production. While IIoT adoption is still in a nascent stage, there are some industries that have taken the first mover advantage and have started demonstrating readiness use cases.

The Smart Factory

The adoption of IIoT has reshaped traditional factories to create smart factories. The systems work with interconnected machines and real-time data exchange that merge the departmental communications along with unified operations and information systems.

How is IIoT making factories ‘smart’?

IIoT has revamped how the traditional units worked. The slow and manual processes are now automated processes with M2M communication. This can be easily demonstrated through an example of how Smart Factories deal with preventive maintenance.

A smart factory has machines, sensors, databases, and humans all working in sync with each other. Sensors within machines can automatically notice a fault and the software logic sends an automatic alert to the right human to analyse the cause behind the fault. With Artificial Intelligence incorporated, machines determine the cause of the faults and go beyond predictive to prescriptive approach pre-empting problems before they exist. This in return reduces the maintenance cost and increases uptime of the factory by introducing parameters to fix machines with accuracy. In-return this leads to increased shelf-life of components and less-time involved in problem detection and rectification.

Energy & Utilities

The Oil & Gas industry is embracing IIoT with a multitude of benefits. Now the energy and utilities have an ability to easily sync data and simultaneously operate across multiple locations. This is made possible with the adoption of cloud, and installation of sensors that capture real-time data on the operating conditions of assets, monitor physical conditions such as temperature, pressure and humidity, and even environmental conditions. The practical scenario here is that Oil & Gas companies are remotely controlling their drills and monitoring the earth’s crust by remote control sensors and maintaining the flow of resources.

Logistics

With so many moving parts in a logistics system, from factories, collection points, and the transport network, it was difficult to maintain and manage a single view of the entire process. Through an ecosystem of sensors on the machines and vehicles covering the entire supply chain, it is now possible to access real-time data. It allows advanced functionalities such as virtually positioning hundreds of vehicles and optimising their route. In the process saving energy and reducing the time for delivery. The consequence is reduced costs for fuel, vehicle maintenance, and staff, plus increased customer experience through shorter and more accurate delivery times.

Other Industries – Promising the change

The adoption of IIoT will go beyond the early adopters and revolutionise several other industries. The Transportation industry is ripe for transformation given that infrastructure is being strained and margins reduced. The challenges of demand and aging infrastructure can be best handled by IIoT.

“The success of smart cars will eventually depend on how ‘smart’ the infrastructure is,” opines Vernon Turner, Executive Analyst, Ecosystm. “Several smart cities are already thinking along these lines, and adoption of IoT in Transportation is set to rise exponentially.”

Another industry that will benefit immensely from IIoT adoption is Healthcare. At the moment, asset management IoT systems have been adopted by several organisations, as in-patient remote monitoring systems that allow clinicians to monitor and analyse patient data remotely.

“The real value of IoT will be realised when clinicians have a clear workflow that allows them to monitor patients outside the hospitals,” says Sash Mukherjee, Principal Analyst, Ecosystm. “In the past, healthcare organisations have been influenced by the Manufacturing industry – by Lean and Six Sigma. They will benefit from implementing Industry 4.0 technologies, that will transform not just the provider organisations, but healthcare in general.”

Turning IIoT into a Profit Engine

Given all of this information about IIoT you may be thinking about the ROI, associated costs, benefits and the industry-wide exposure of the Industrial IoT. It is imperative that companies large & small are embracing Industry 4.0 change. IIoT is benefitting businesses through differentiated offerings, a creation of newer revenue streams and increased monetisation of existing offerings.

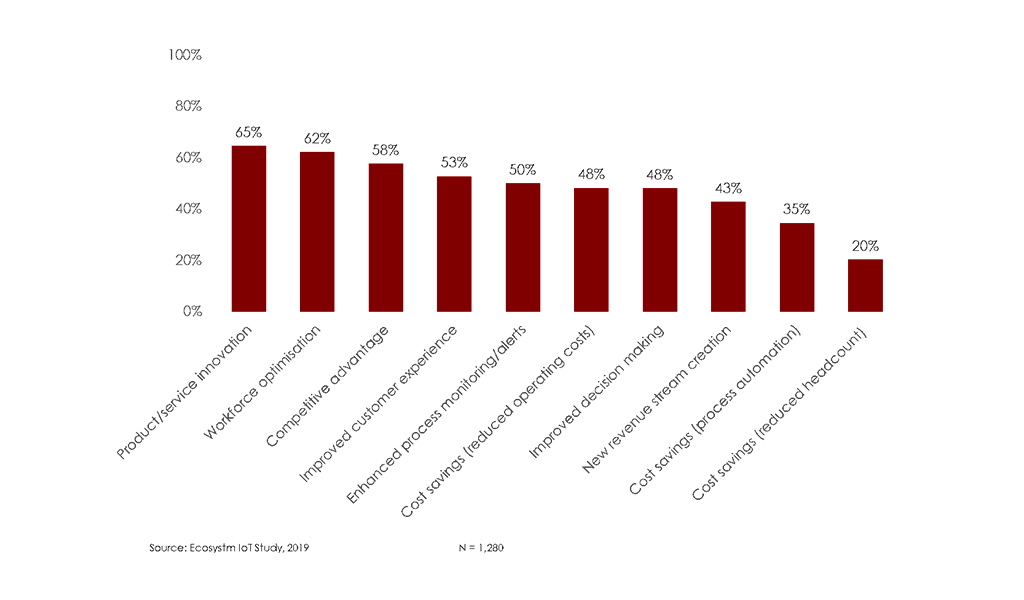

The Ecosystm IoT Study, 2019 looks at the drivers of IoT adoption across industries.

The data shows that the key drivers of IoT adoption can all affect the profit margin of an organisation.

- Innovation. In today’s competitive world, innovation in product designing and service delivery is directly related to a positive impact on profit margins. Organisations are looking beyond cost savings through their investments in IoT and are using IIoT to bring new, innovative products and services to the market. They are looking at creating innovative businesses that can leverage technology and offer cost savings.

- Workforce Optimisation. It is impossible to bring change without workforce optimisation. Organisations are working on the valuable insights offered by IIoT systems which further provide ways to optimise the workforce and accelerate productivity. Implementation of automated production units and the reduction of manual labour is bringing both productivity gains and increased profits. It is also boosting employee morale – happier employees impact the profitability of organisations, reduces turnover, improves customer interactions, and promotes more job ownership.

- Customer Experience. Customer expectations have gone up and so have methods to improve customer experience. Organisations are taking IIoT seriously, as it’s unleashing capabilities to improve processes throughout the product life cycle while also improving product quality through better QCs. Feedback to product improvement time has reduced – customer features and product improvement requests can now be handled more efficiently, based on customer data.

Businesses that fully capitalise on IIoT systems are successfully building a competitive edge through their innovative products, optimised workforce, and differentiated products and service offerings to enhance customer experience.

What Lies Ahead?

As IIoT percolates into other industries, we will potentially see a new industrial revolution. This has obviously been attracting investment and technology companies quickly to offer related technology offerings that tech buyers would do well to consider along with IoT.

Cloud

Data management will become an obvious challenge with IIoT-driven data proliferation. Already the industry has been talking about going beyond cloud to “fog” computing. The real value of IIoT will be realised when the solutions become able to operate on the Edge. This will see an increased uptake of SaaS offerings that will be required for quick and accurate data-driven decisions.

AI

AI will eventually go further than basic machine learning and incorporate deep learning for better predictive and prescriptive analysis. IoT devices with embedded AI will truly revolutionise industries. This is another technology area that tech buyers should keep an eye on, irrespective of the industry.

Security and Risk Management

An explosion of IIoT devices and data will bring new risks. Cybersecurity experts and teams will be required to constantly monitor vulnerabilities, follow security best practices and eventually predict breaches.

The Future

Industry 4.0 is very much a buzzword in certain industries, with several advanced organisations already following the business and technology practices. Naturally, there are still many companies that do not see the need for new technology or would rather invest in other areas.

For organisations that are looking to modernise, innovate and remain competitive, Industry 4.0 is a good benchmark of how technology can be leveraged. IIoT is a key enabler of Industry 4.0 and has the potential to deliver benefits to majority industries through increased intelligence and curated data – the question is how soon we can witness it on a scale.